NEED TO GET YOUR PRODUCT IDEA MADE?

We Manufacture

TOOL is an award-winning product design agency. But design does not stop at a prototype. Our phase-based process takes you into manufacturing and full production. This is the case whether customers are using our design work, or a design they already have. TOOL has an office in Shenzhen, China that can oversee production tooling, source parts, manage production, and obtain product certifications such as UL, CE, and CSA. Our team in the US and abroad can help to make sure that your product meets your quality standards and specifications.

We can also build tools and products domestically if the product needs to be Berry or ITAR compliant, or you have another strategic reason to produce in the United States.

The Technical Feasibility of Your Product – Being Aware of the Challenges

Many products can seem like easy solutions to build but, in fact, are complicated to make. Perhaps the design is not optimized for molding or extrusion? Perhaps it relies on exotic materials which make production costly and time consuming? If TOOL designed it, you are ready to go. On the other hand, if you have an idea that is a product ready to launch we can dissect and analyze to make sure it is ready for production. The goal is to get you the best possible profit margin and to ensure your commercial success.

To learn more, feel free to contact us here. Also, we are happy to sign an NDA to review where you are. Simply sign and return this Mutual NDA to get the ball rolling, and we will countersign and return to you.

If you are at the idea stage, or have a patent but no completed design, see our design services here.

DFMA (Design for Manufacturing and Assembly)

All products we design are designed for production. We are experts in all manufacturing processes used today. Most products you buy and use are composed of these basic processes. Avoiding exotic, complex manufacturing processes should be a focus to control tooling and assembly costs and maintain maximum gross margins for your business. Most products in today’s consumer environment are composed of the following and most likely your solution will be made using the following processes:

Injection molded plastic

Diecast metal

Sheet metal

Metal and plastic extrusion

Vacuum forming of plastic

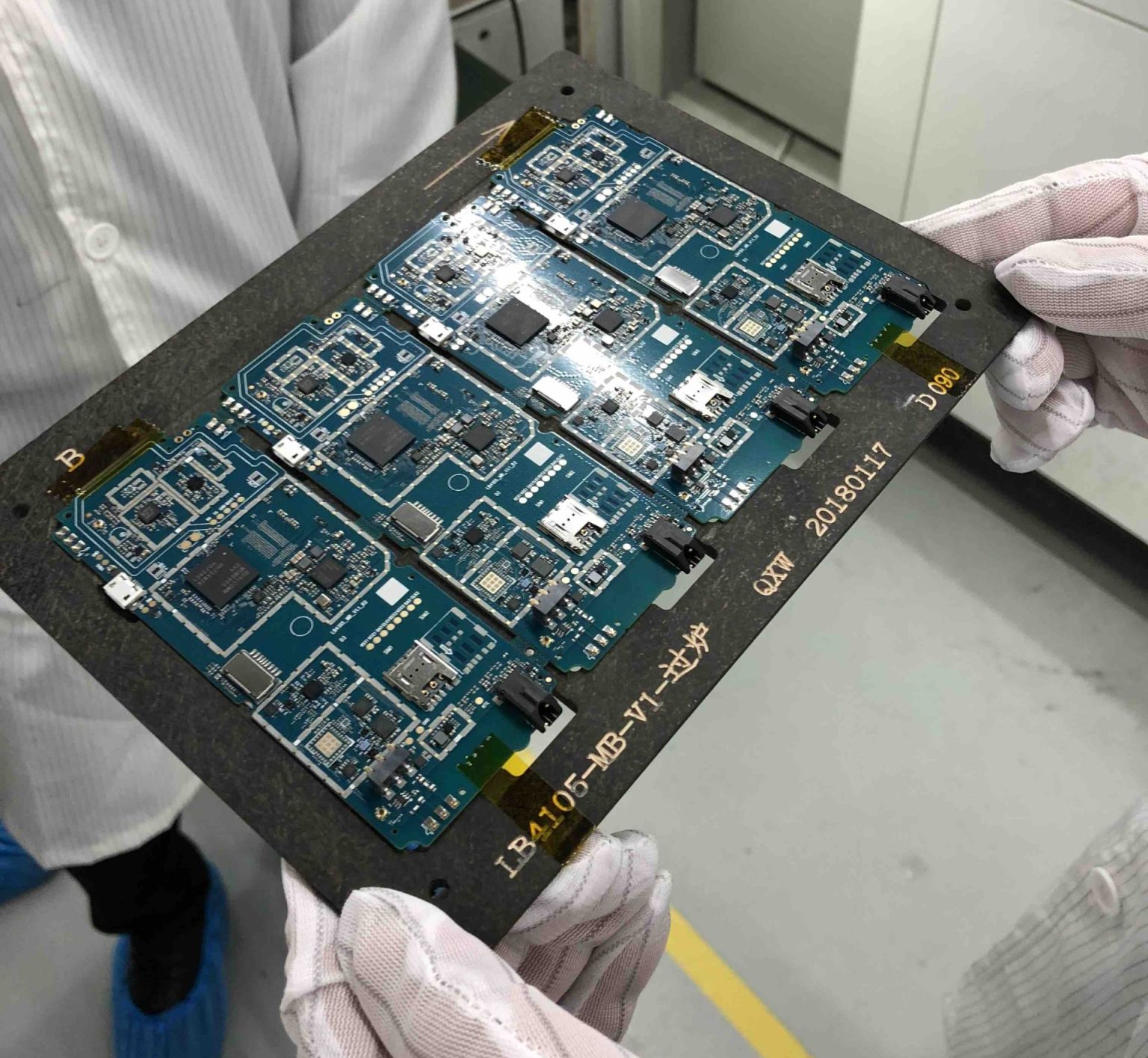

PCB fabrication

All processes require thinking ahead about setup, and most need tooling to fabricate the part. We ensure that all parts of your design are constructed to ensure the lowest possible tooling investment. Part design for manufacturing is a key part of our engineering process. A good design is also an easy design to assemble. Z-axis assembly should always be a fundamental aspect of every design.

Cost (Product and Tooling)

Cost is always a driving factor in any design or any product looking to enter the marketplace. If you don’t know your customer and their capacity to spend on a solution see our insights and research services here. The general principal of capitalism is to make the product for the least amount and sell it for the maximum amount the market is willing to pay. Costs of the product as a whole are a function of the cost of the parts, the assembly and any shipping, transport, and tariffs. Tooling costs can be a large capital expense. The charge can be paid over time, amortized via the product part price, or paid at tooling completion. Our goal is always to design parts for a process with the least amount of complexity to reduce costs.

Supply Chain, Tooling and Production Management

Our office in Shenzhen allows us to facilitate and manage the supply chain of purchased components, tooling, manufacturing, and production. Having boots on the ground allows us to monitor the progress and mitigate any issues arising which may alter the schedule or incur additional costs. Our office is staffed with a team of manufacturing engineers with years of experience in all types of manufacturing. Asian or domestic, we can help manage your manufacturing. It can feel intimidating, but we do this every day. We guide the process and show you the light at the end of the tunnel!

Let us know here you are in your process. If you at the early stages, perhaps just a sketch, start on this page.

However if you have a design, including full 2D and 3D CAD files ready to go, simply download our NDA and email it back to us here.

Here is our promise to you: TOOL can get it made.