Our Process

Each project is unique; therefore, our design process is scalable to any need and flexible enough to work with any size company. Whether the requirement is a full scale program to revolutionize a product category, or simply to evolve an existing product line, Tool can provide the correct level of resources and services to fit the needs of all our clients.

Our design process consists of planned iterations to incorporate the multidisciplinary perspectives of our staff, partners, and clients. What appears to be a linear design process is actually an integrated team of designers, engineers and researchers working hand-in-hand throughout each process phase.

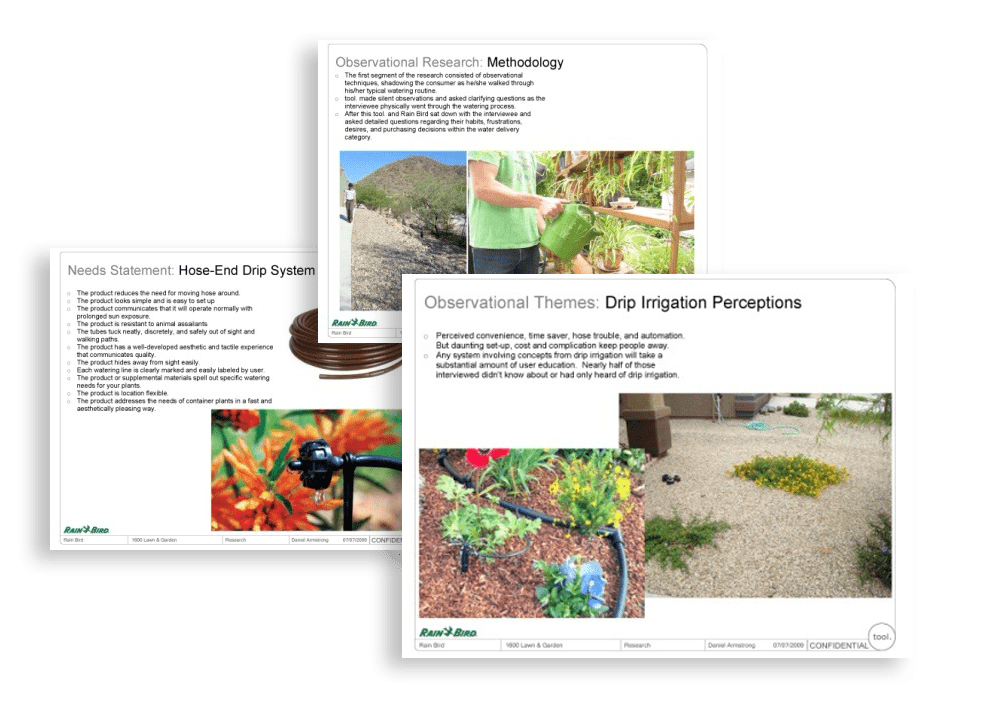

Relying on assumptions can be dangerous

Successful product design starts with a clear understanding of the consumer’s needs and wants. Our research services include in-depth consumer interviews, observational & ethnographic research, competitive audits & benchmarking, user needs assessment and patent & technology assessment.

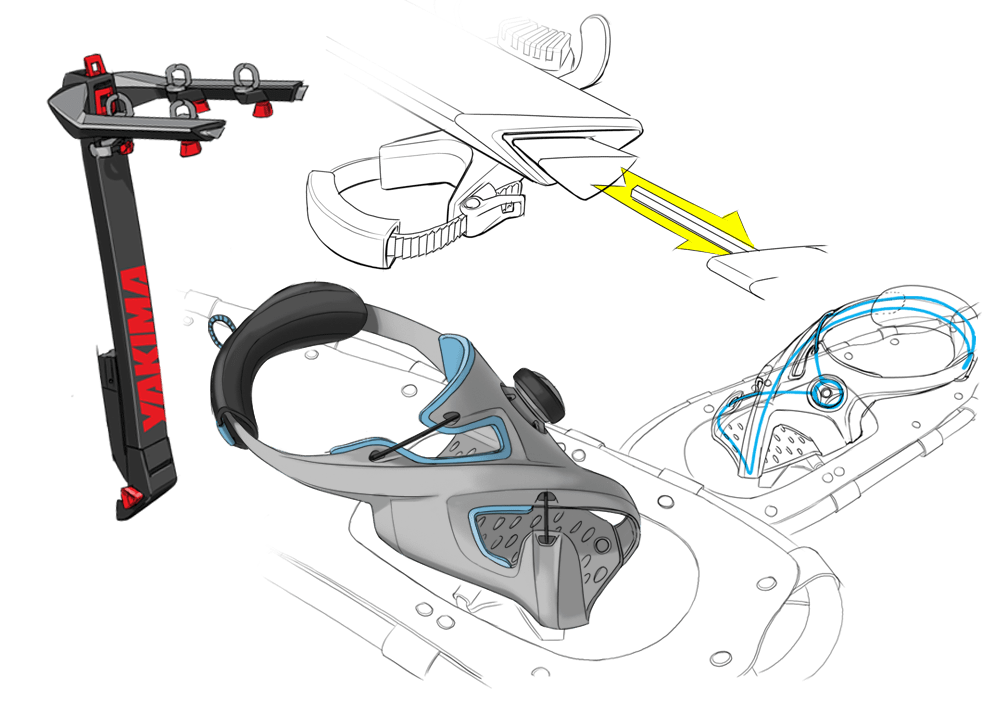

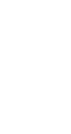

1. Ideate

Iterative exploration

Rapid studies of Form and Function

This iterative process allows for the full exploration of ideas, concepts and alternatives, while involving all stakeholders in critical decisions regarding concept directions.

2. Refine

select directions

Details and specifics

Selected design solutions will be modified to further enhance design language, user features and overall part geometry.

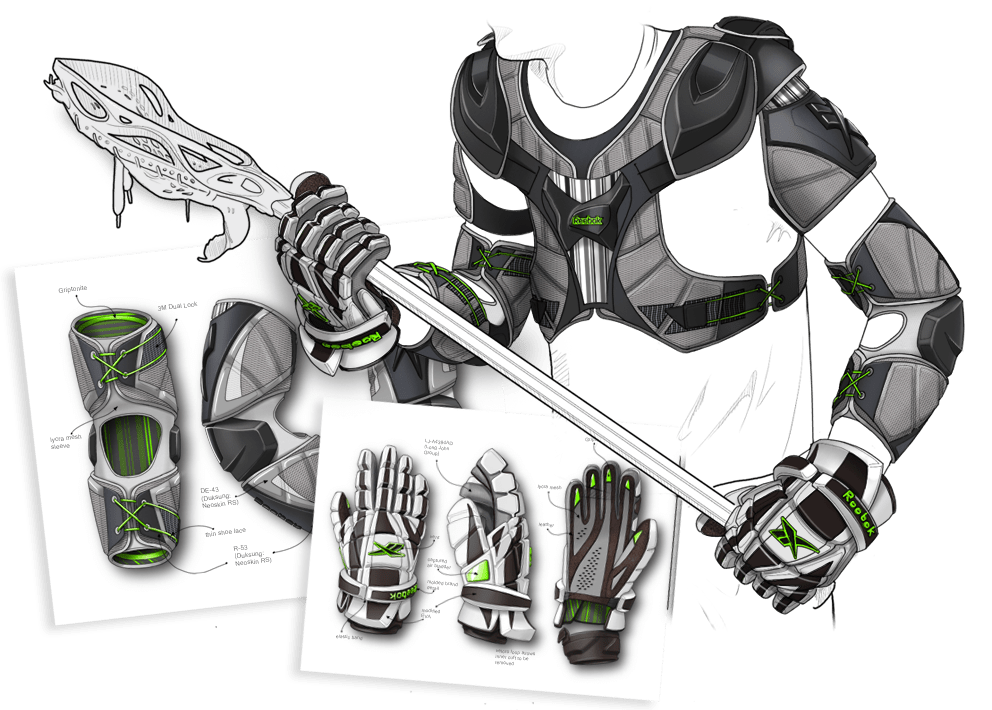

3. Engineer

mechanisms. assemblies. structural analysis

Final Part Geometry and bills of materials

Issues of material selection, manufacturability, assembly, internal & external features, structural & thermal analysis, as well as safety compliance, are addressed in this phase.

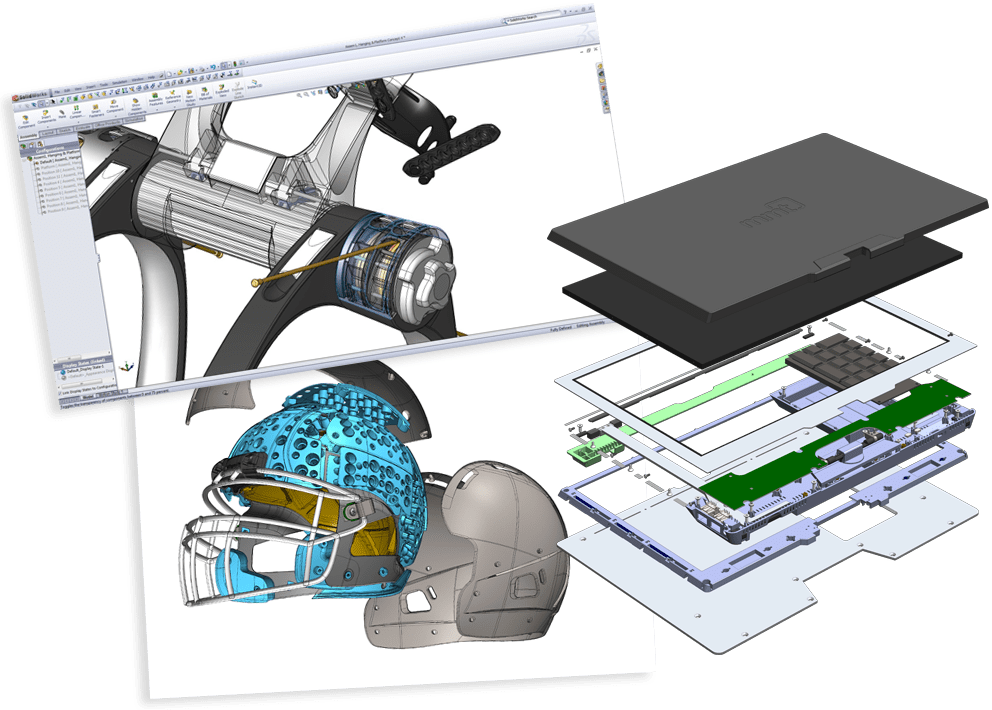

4. Prototype

quickly validating concepts

Allows for feedback at critical decision making points

Our in-house capability and our relationships with a variety of machine shops and rapid prototyping vendors lowers prototyping costs, reduces expensive revisions and gets products to market faster.

5. Make

COMPLETE MANUFACTURING SUPPORT

EVALUATING QUOTES AND PLANNING YOUR MANUFACTURING

We have extensive experience in both domestic and offshore markets, and our understanding of these markets allows Tool to help you efficiently plan your manufacturing strategies.

More here on getting your design made. Manufacturing.