robotic pallet

RESEARCH | INDUSTRIAL DESIGN | ENGINEERING | PROTOTYPING

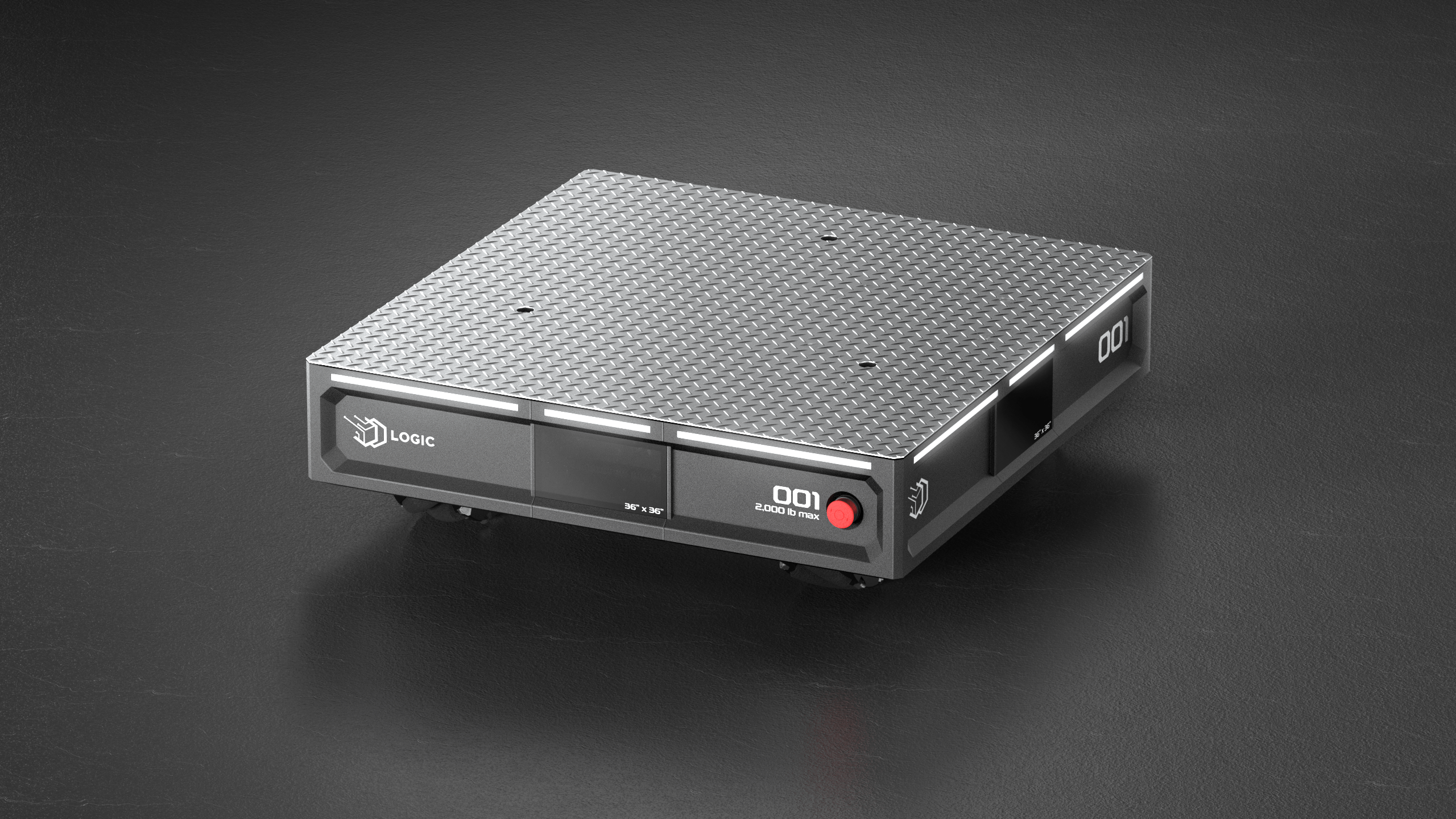

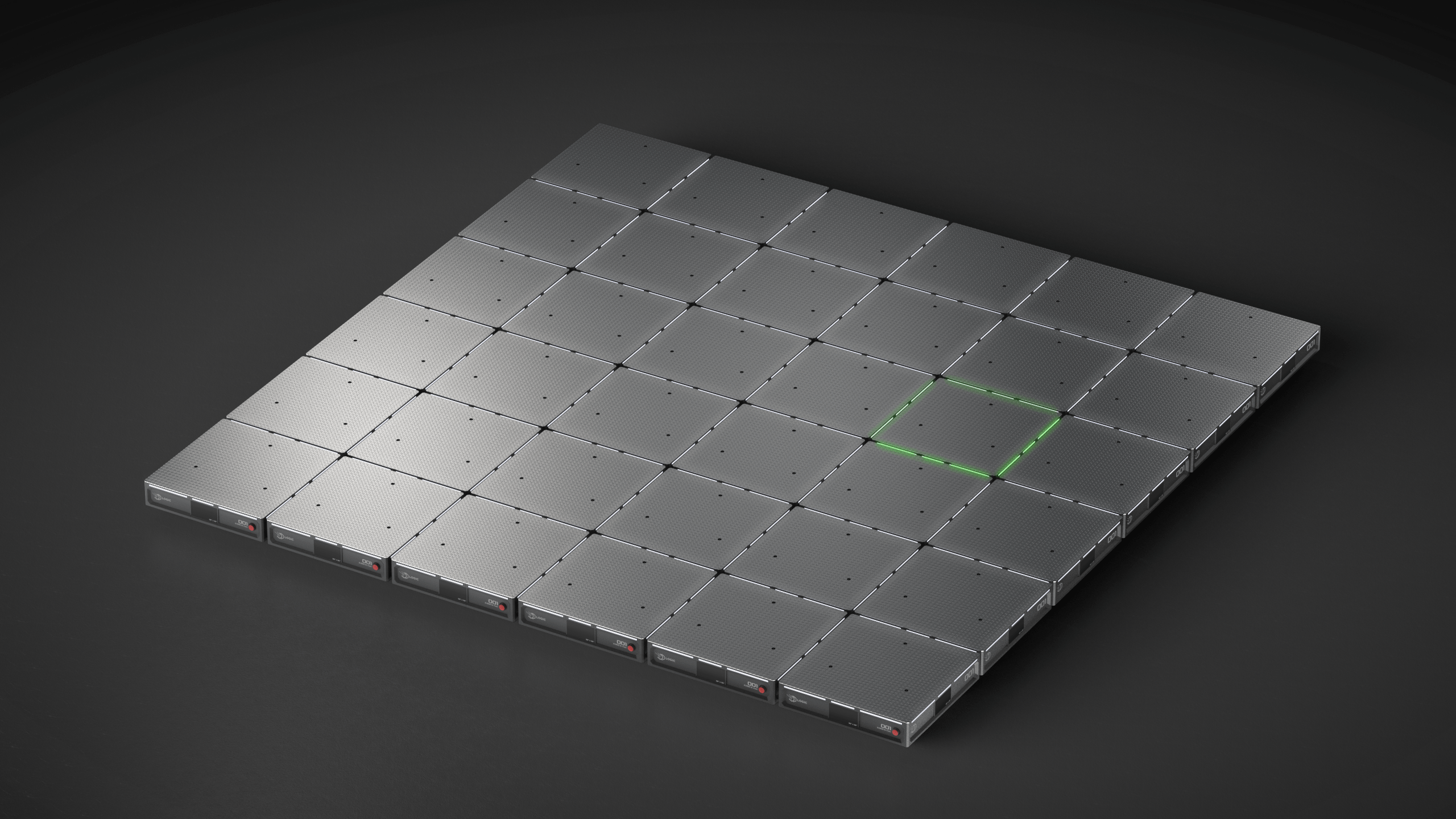

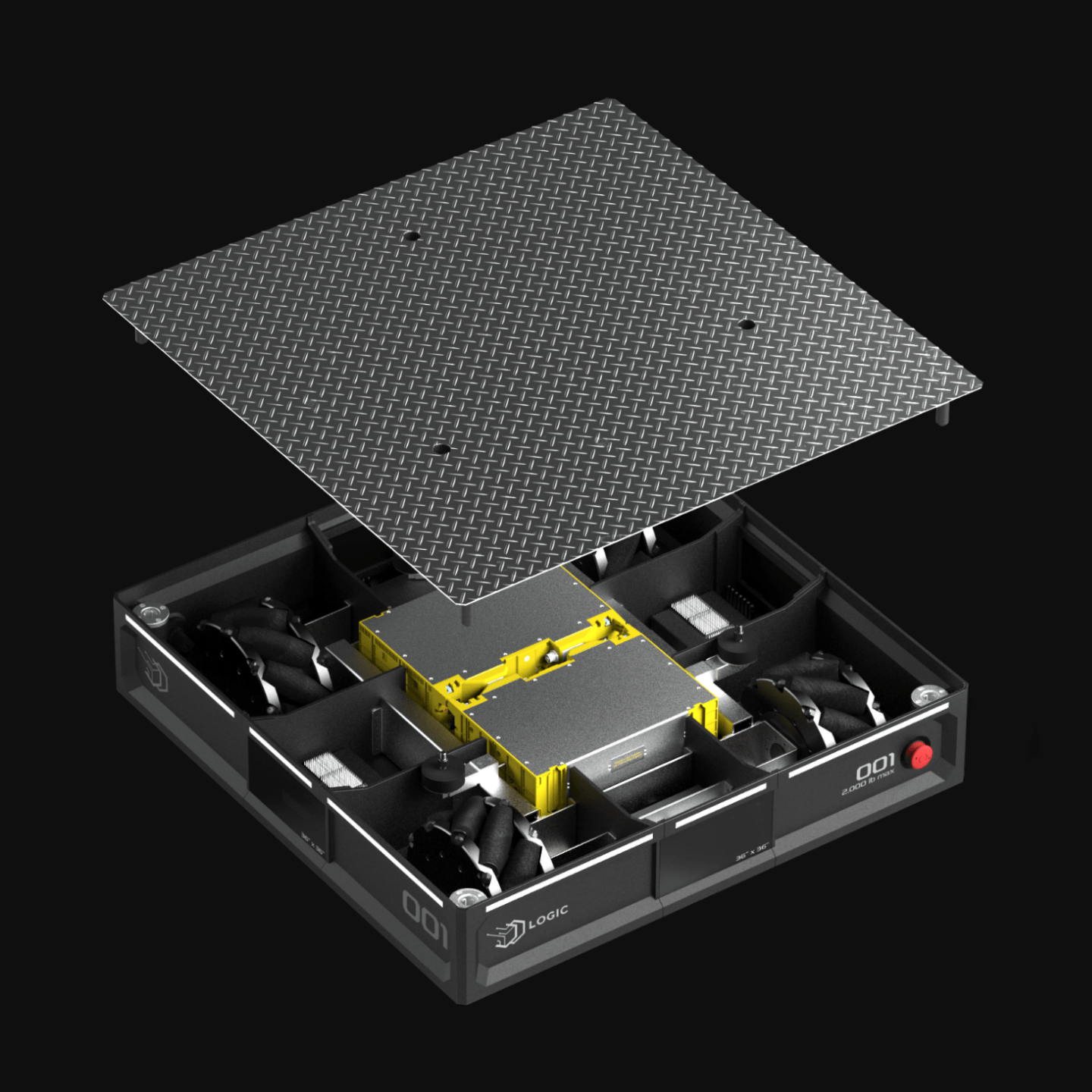

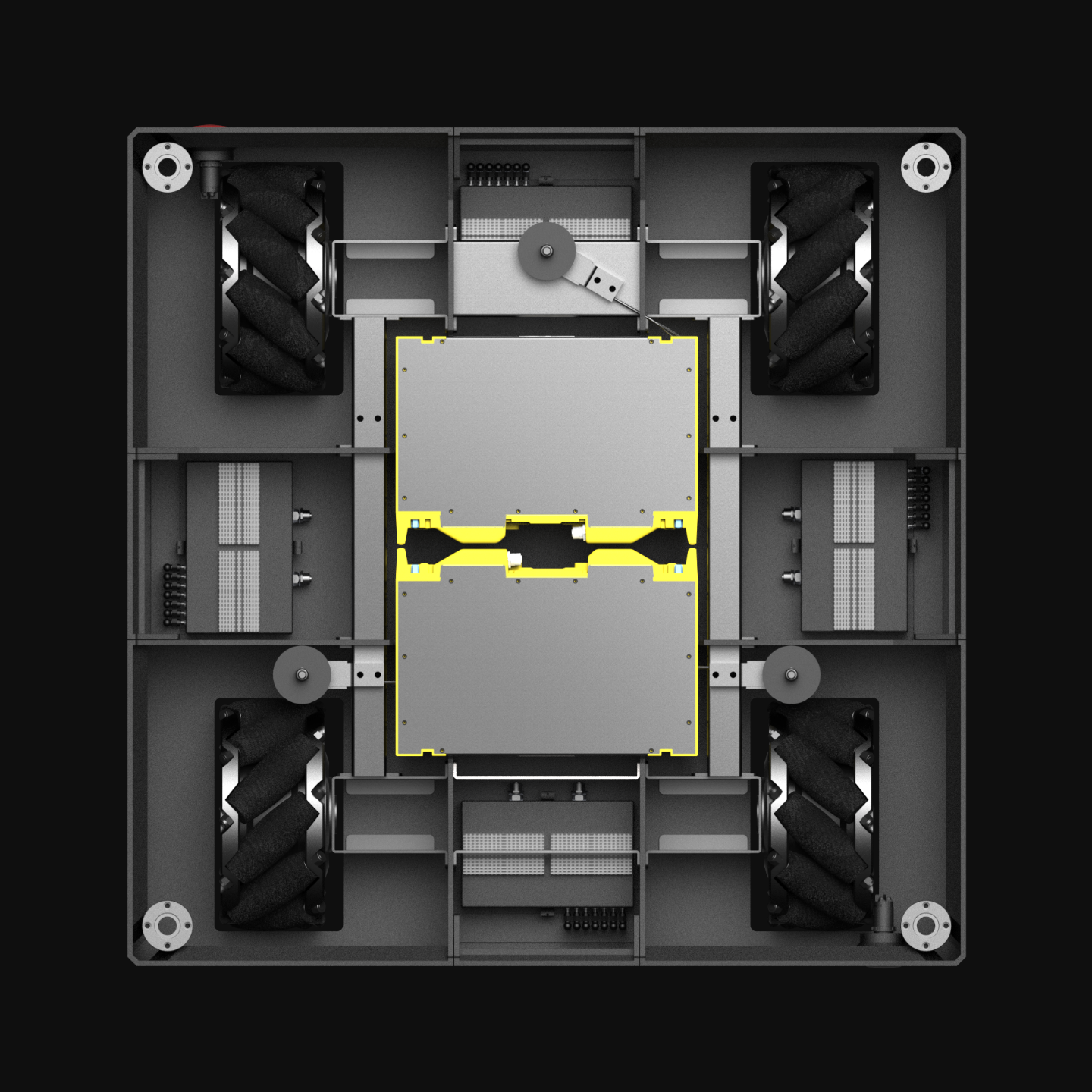

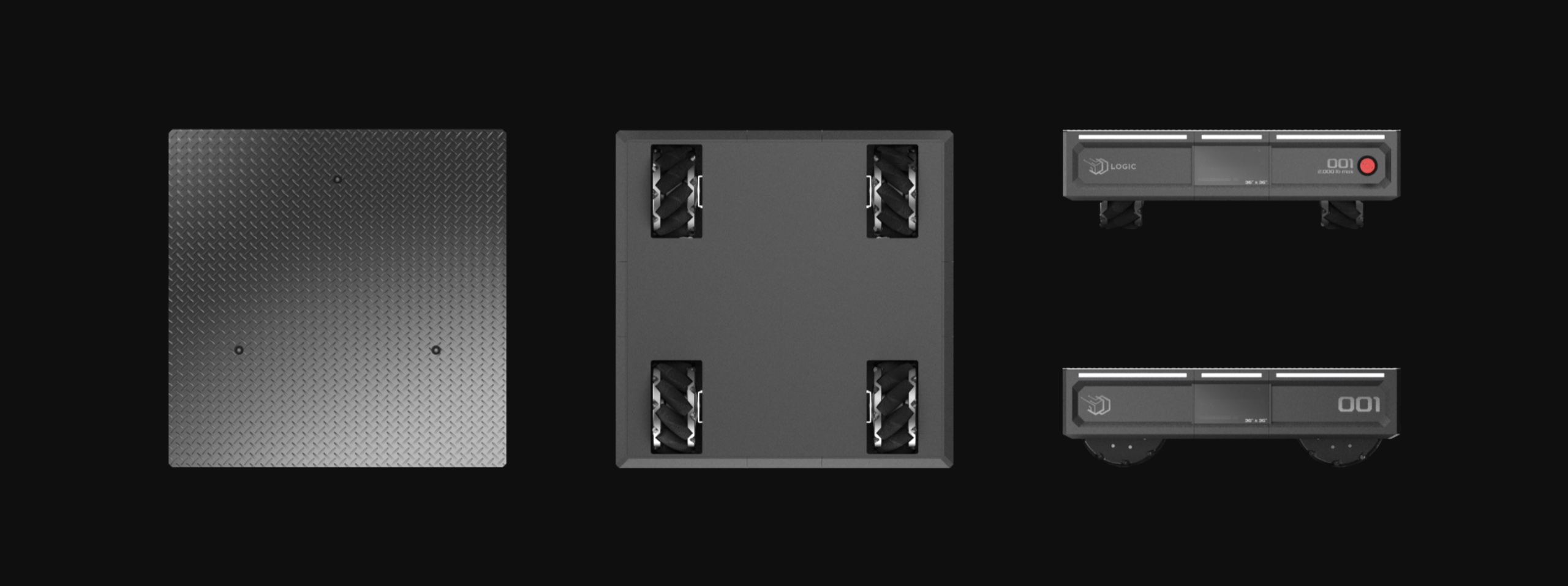

Logic Pallet set out to transform warehouse logistics with an autonomous robotic pallet: turning the pallet itself into both the unit of storage and the vehicle of transport, with the potential to shrink warehouse footprints and cut labor costs. Logic Pallet engaged Tool to advance a next-generation robotic pallet toward a rugged, production-minded v2 prototype. We began by grounding the concept in real warehouse constraints: common pallet sizes, hose-down cleaning, stackability, and simple field service. Industrial Design explored a sandwich chassis that looks at home on a loading dock, with protected corner lighting, accessible e-stop, and a grippy top surface. We kept the experience straightforward and aligned with the team’s goal of a cost-sensitive platform.

Engineering translated the refined ID into SolidWorks assemblies with early FEA and a “body-in-white” approach to prove structure before skins. We retained four load cells with side-load mitigation, sized the wheel package for capacity and ground clearance, and planned IP-minded enclosures for electronics and charging options (dock or inductive). We aligned on a clear path: lead with a 40×48 base and a 36×36 variant, integrate early with the contract manufacturer, and prepare a pilot build. Tool delivered a coherent chassis architecture, load-case rationale, and a step-by-step prototype and test plan, positioning Logic Pallet to scale with their industry partners.