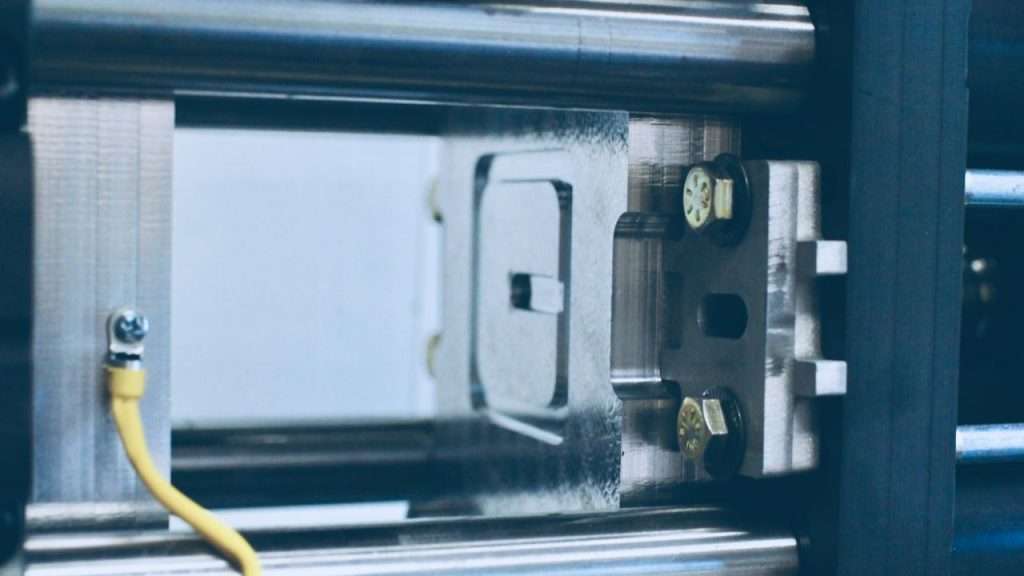

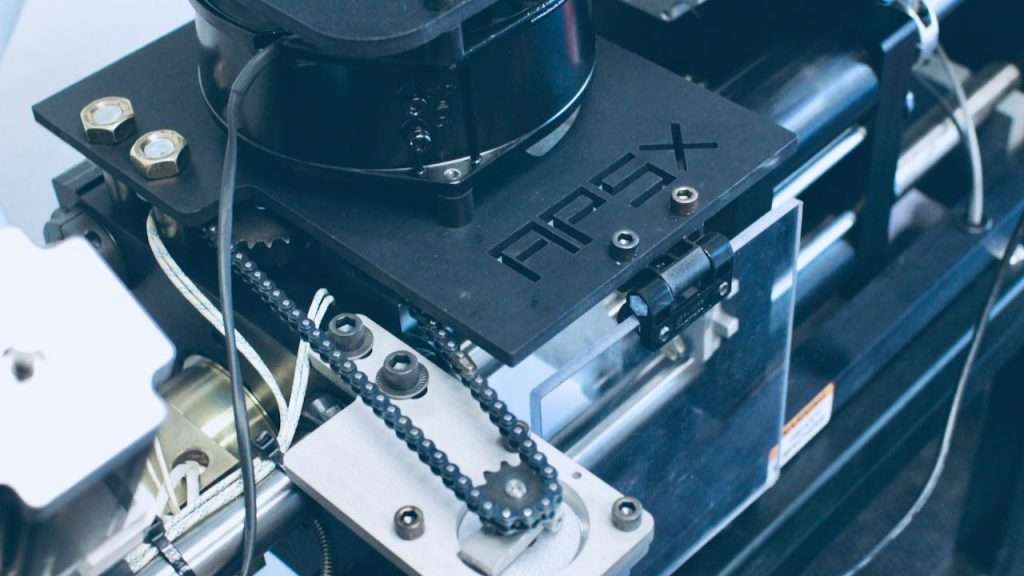

When it comes to product development, good planning and a well-honed process are key to avoiding pitfalls and to helping our clients bring new products to market as efficiently and cost-effectively as possible. One way TOOL avoids costly mistakes is to iteratively build, test, and refine product concepts throughout product development. We leverage a number of in-house 3D printers, a laser cutter, a CNC, shop tools, and– as of this past week– a brand-spanking new APSX Plastic Injection Machine. Unlike many other design firms, we’ve focused on design and engineering for actual production for our entire 21+ year history. So, we know intimately the ins and outs of design for manufacturing in all its material and process flavors. Now having the ability to injection mold small plastic parts in-house takes our desire to build-test-refine on our customers’ behalf to another level.

We are just warming this puppy up with some test tools, but it will soon be spitting out our own custom parts — designed, engineered, and machined all at tool!

Visit www.apsx.com to get more information about our new APSX injection machine. Let’s design our world for the better!